ENVIRONMENTAL ATLAS HAMBURG

Environmental Atlas is a

collection of articles of

environmentalist groups at

Hamburg, offered in an uniform

format of text and maps. Its first

edition appeared 1992, edited by

"Foerderverein Umweltschutz

Unterelbe", an independent

environmental library. In 1997 an

internet version was launched,

which at the time is prepared to

appear under its own URL:

www.umweltatlas-hamburg.de

4.1

Norddeutsche Affinerie

bottom

History

Streetnames like "Copper Mill

Way" give hints to the

Hamburgian tradition of copper

trade and copper processing. When

Hamburgian ships began to sail

tropical seas, the vessels' hulls

were plated with copper sheet, to

protect them against fouling.

Public buildings, churches, and

merchant buildings often got a

copper roof because of its

durability.

The precedent of Norddeutsche

Affinerie was a gold and silver

smelter, operated by Salomon Beit.

A fire in the year 1780 is noticed

on the city's record. Beit's

heritage was expanded, to include

copper smelting in 1846, and the

factory relocated from the city to

the opposite bank of the river

Elbe. The new factory "Elbe

Copper Works" was permitted

by the Hamburgian authorities

under the condition, to dilute the

smelter smoke through an 85 m

chimney, the tallest of its time

in Germany. Smelter smoke was

known as hazardous because of its

arsenic content. After going

bankrupt, the company was

resurrected, changing its name to

"Norddeutsche Affinerie"

in 1866. The word

"Affinery" signifies,

that the utility does not merely

produce raw copper, but purifies

it and applies a variety of

metallurgical processes. The

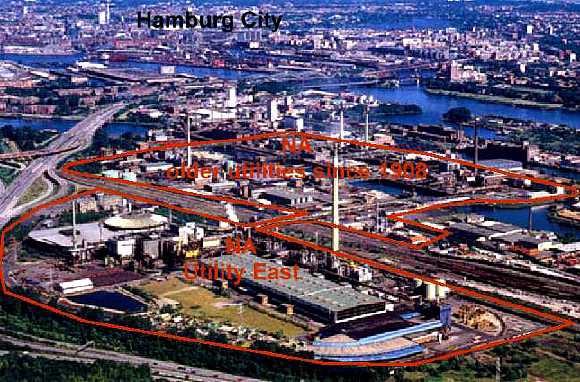

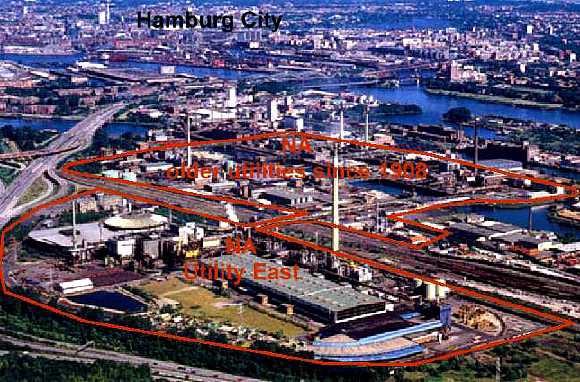

factory was relocated again in

1908, to the most remote eastern

corner of the Hamburgian harbour

at that time, where it remained

till today. Chimneys grew taller.

The company today

In 1998 2,200 workers produced

365,000 tons of copper. 245,000 t

came from copper ore concentrate,

120,000 t from scrap. 500,000 t

sulfuric acid are an inevitable

byproduct, when sulfidic ores are

roasted. Gold, silver, and minor

quantities of platinum metals,

that accompany ores and scrap, are

recovered from the electrolytic

purification of raw copper, and

yielded 17 t gold and 370 t

silver. Sales in 1998 reached US$

1.25 billion, the net profit paid

to shareholders was US$ 26 mill.

100 Mio m3 of surface water,

mainly for cooling, taken from the

river Elbe, and an area of 50

hectares, indicate the size of

industrial operation of that

company.

Impact to Environment

In the course of decades, Affi

applied a large variety of

production schemes. Because of

their skill to recover valuables

from scrap, Affi people called it

"the metallurgical

ashtray". Besides the bulk of

copper and its byproducts, various

smaller production lines left

their footprints to enviroment, to

air, water, and soil. 15 years

ago, 50,000 tons/year of lead were

part of Affi's offers.

The largest weight of emissions

has been, and still is,

sulfurdioxide from the roasting of

coppersulfide ores. When roasting

gas has passed the sulfuric acid

assembly line, 1,500 tons/year of

SO2 leave the chimneys today. 15

years ago, efficiency of this

device was poor, so more than

3,000 tons/year were emitted.

Sulfurdioxide forms acid rain,

that detoriates trees, buildings,

and even copper sheet roofs.

Various trace metals accompany

copper ores. Some are recovered

completely, like silver and gold,

but some are not worth the effort.

Thus lead, cadmium, and arsenic

were discharged to water and air

in considerable quantities.

The "Environment

Protection Group

Physics/Geosciences",

abbreviated the "Geos"

(wantoks of "Save the

Elbe") conducted a large

research program of metals

contamination in the Hamburgian

harbour from 1978 till 1981. As

students at Hamburg University,

they had access to analytical

laboratories. A small channel in

the Hamburg harbour systems was

the first target of Affi's

discharges. There, the Geos found

the typical residues of Affi's in

the sediments. Concentrations are

displayed as 10fold units (copper

20fold) of standard background of

unaffected sediments. Some

concentrations reach the level of

ore deposits.

By numerous publications

of the Geos, the problem was

brought to knowledge of the

public, and even to Hamburgian

authorities. First, the Geos were

blamed, to work not scientifically

sound. Then, the Department of

Buildings and the Department of

Environment ordered their labs, to

investigate the contamination of

soils throughout the state area.

The result was frustrating,

because the findings of the Geos

were more than confirmed.

Following the dominating direction

of wind, highest concentrations of

arsenic and copper were found in

soils. It seemed not advisory, to

grow certain crop, that accumulate

copper and arsenic, in an area

northeast of Affi. However,

authorities tried to keep their

findings secret. But the news

leached to the leftist newpaper

"die tageszeitung", that

launched an extra edition titled

"Deadly Threat by Northgerman

Affinery".

Solid waste is formed

from exhaust gas purification, and

slags. Exhaust gas scrubbers have

the purpose to remove

sulfuroxides, and preciptitating

this by addition of lime. Trace

contminants like arsenic are

removed, too. The resulting sludge

of former years was disposed on an

area, where now utility east has

been built. Affi is founded firmly

on its own toxic waste, which

means, it will remain there, and

possibly spoil ground water,

because it cannot be transferred

to a safe place. Slags, iron

silicates with traces of copper

and its companions, are turned

from waste to products, that may

be sold. Slag stones serve to fix

river banks, because of their high

specific weight. Organisms like

algae and hydrae, that grow on

slag stones, show significant

aberrations.

It's all legal

Any operation of a company has to

be permitted by state authority.

So does Affi. Any permit, given

long time ago, will last till more

stringent law will require better

performance. However: new

legislation must not lead to

economically undue restrictions of

utilities, that already exist and

are permitted. When federal

goverment and parliament imposed

more stringent laws on emissions

from utilities, Affi and most

Hamburgian companies rejected the

orders of the Environmental

Department. It took negotiations,

to move companies to improve

environmental performance. Affi

was subsidized with US$ 20 million

by state government, to refurbish

its plant.

Control of permits is poor.

Through 50 pipes waste water is

discharged. From only few of them,

samples are taken by the

Environmental Department. 15 times

a year, for two hours, waste water

is sampled, which means 30 hours

of 8760 hours of the year.

Sampling occurs stochastically,

but not at night nor on sunday,

and is not correlated to the state

of production process. Discharge

values published by the

Environmental Department. are by

no means reliable or

representative. Emission to air

values depend on what the company

declares to the Environmental

Department, there is no

independent check.

Water quality control by the

Environmental Department. never

aimed at sources of contamination.

Till today, the measurements of

"Geos" come most close

to the discharges of Affi. The

Environmental Department. always

kept a distinguished distance to

any discharge pipe.

Never trust a company!

1988 people in Billstedt, a

quarter of Hamburg 8 km northeast

of Affi, frequently complained

about the smell of burned

plastics. The Environmental

Department knew no answer, but the

"Billstedt Environmental

Noses" followed the track,

that lead to one of Affi's

smelting ovens, were electronic

equipment scrap was added. Slowly

burning plastics, especially

polyvinylchlorides, do not only

produce bad odour, but highly

toxic byproducts like dioxins.

Confronted with this finding, the

Environmental Authority admitted,

they had given a preliminary

permit to Affi for a trial phase.

Affi had to stop its dirty

practice, applied for an unlimited

permit to burn electronic scrap in

a hotter and more modern furnace,

and finally got it. If not for the

"Noses", Affi would have

continued with the old device till

its technical breakdown.

Any company wants to make as

much profit as possible,

environment gone, money come.

State authorities are always

supportive to business. This

explains the need for control by

independent environmentalist

groups. May Affi declare to be the

most environmental friendly copper

smelter of the world, we will

check that first.

Klaus Baumgardt

Sources

- Umweltschutzgruppe

Physik/Geowissenschaften:

Gl”nzende Gesch”fte - Umwelt

hin, Geld her; (Environment

Protection Group

Physics/Geosciences: Bright

Business - Environment Gone,

Money Come) Hamburg 1985

NA Business

Reports NA Business

Reports

.

top

Index of Ok

Tedi pages Index of Ok

Tedi pages

back to

Homepage back to

Homepage

|